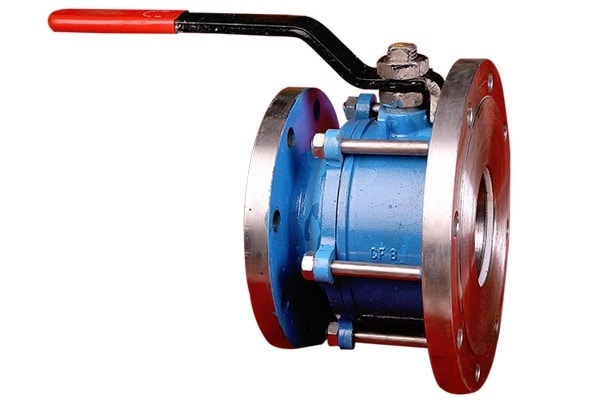

Flush Bottom Ball Valves Manufacturer and Supplier From Ahmedabad

Our organization has been actively engaged in manufacturing, exporting and supplying a premium quality Flush Bottom Ball Valve in Ahmedabad, Gujarat, India. The flush bottom valves are manufactured using rich grade raw material and advanced manufacturing techniques. These valves are designed to provide drainage and dead space free shutoff for reactors, vessels and storage tanks. We are precisely tested on several quality parameters to ensure their optimum reliability and durability. Flush bottom ball valves are designed by using optimum quality material and latest technology. These are available at most affordable market rates. Our products are high performance and longer service life.

Key Features of Flush Bottom Ball Valves

- Unique design of “IVE” Flush bottom ball valves assures “Zero Dead Leg Area” above the ball where it tends to close.

- Casted and fabricated in all available metallurgy, Carbon Steel, S.S 304, S.S 316, S.S 304L, S.S 316L, Alloy 20, Hast alloy and as per special specifications.

- Valves available in the range of 25 NB to 200 NB and in BS, ANSI, DIN, standards.

- Screwed/ bolted stuffing box (Gland), easily adjustable and with repack able service.

- Anti blow off proof stem.

Specification of Flush Bottom Ball Valves

| Application | Isolation |

| Features/Benefits |

|

| ANSI class / Rating | 150-300# |

| Design Standard | ANSI B 16.5 |

| Testing Standard | API 598 |

| Size | 50-300 mm NB |

| M.O.C | ASTM A216 Gr WCB, ASTM A351 Gr CF8/CF8M/CF3/CF3M, Alloy-20, Hast-Alloy-B,C , Monel, AISI 304,304L,316, 316L, Duplex, Super Duplex etc. |

| Ends | Socket Weld, Butt Weld, Flange End |

| Operation | Manual, Pneumatic, Gear operated |

The flush bottom ball valves are designed to completely seal off the outlet nozzle at the inner vessel wall. This prevents solids/liquids from accumulating and solidifying in the outlet nozzle neck and preventing discharge of the vessel contents. In addition, it prevents un-reacted material from collecting in the nozzle. There is a flush bottom ball valve with a special design for the inlet flange. This can be permanently attached to the bottom of the reactor, tank, vessel, or container. A smooth tapered hole and a super short distance between the ball and the bottom allow the medium to be discharged smoothly without accumulating at the entrance. The flush bottom ball valves are typically operated by hand levers or gear units, depending on the valve size, but we also offer pneumatic operated ball valves for automation.